We all know that something that joins pieces together is called an adhesive. However, before going into the adhesive, we will try to discover its exact uses. One unconventional use of adhesive is in the construction. You heard it right. The block adhesive has extensive use in the construction domain. The foundation of any building is in its bricks. Bricks and tiles are kept one after the other with some concrete and adhesive that ensures their strength. There is a specific type of concrete that finds multiple applications nowadays. This unconventional concrete is called ACC.

What is ACC?

The full form of ACC is called the autoclave aerated concrete. We all have an idea about concrete. Concrete is a heterogeneous mixture of cement and other particles that are suitable for building construction. With evolving generation, modification is there in our taste and technique also. As the name suggests, the ACC is a form of concrete with foam texture. This lightweight new form of concrete is the most appropriate component of the new type of building blocks. The ACC block is specially developed by autoclaving a composite mixture of lime, cement, and aluminum powder under high temperature and pressure. The heat curing causes aeration in the concrete texture and makes it lightweight and possesses high tensile strength. This foamy concrete can build up blocks and, the ACC block adhesive can place the blocks firmly to build a strong foundation.

Advantages of ACC Blocks

Sound Repellant- The aerated ACC blocks go through curing them under high temperature and pressure. The foamy texture helps to absorb much of the unwanted sound frequencies. It helps to give the unique sound-proof property of the ACC blocks.

Insulation Done Right- The foamy texture of the ACC blocks gives them maximum air trapping capacity. The spaces in the ACC block helps to capture more air. It helps to impart the insulation property. The ACC blocks do not allow heat to enter the building nor let the heat inside move out of the building. It gives proper insulation to the building.

Seismic Wave Protection- The lightweight and foamy ACC blocks are also seismic wave resistant. The blocks absorb the shocking waves of the earth and prevent the building from collapsing.

Fire-Repellant– The ACC blocks also provide fire resistance to the buildings. As the ACC blocks go through high temperature-dependent curing, they can withstand about 1500 degrees of temperatures. It gives maximum fire protection by absorbing most of the fire-generated heat.

Inorganic Are Saviours- Major constituents of the ACC concrete blocks are inorganic materials like lime and sand quartz. These inorganic materials do not allow the atmospheric water particles to enter. Without the presence of an inappropriate growth medium, the bacteria or melds cannot grow. The ACC blocks are thus melded and pest resistant.

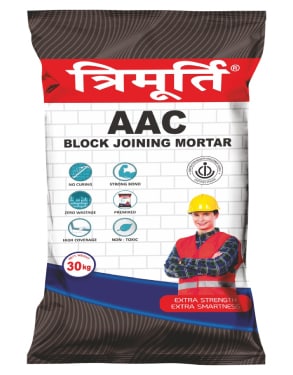

The lightweight of the ACC blocks restricts the dead weight of the building. It causes a decrease in the steel bar requirement by more than 20%. The cement requirement is less in ACC blocks. The overall joint presence is much less as compared to clay bricks. It saves the mortar requirement by almost 60%. It gives an added advantage to the block jointing mortar manufacturers.